The FAQ on IAQ

By T.J. Johnson Cavalier Industries

Features Products Tech tipsControlling indoor air quality during construction can dramatically increase project efficiency, while delivering the highest quality finished product to the building owner.

Controlling indoor air quality during construction can dramatically increase project efficiency, while delivering the highest quality finished product to the building owner. The fact is, there are existing codes and guidelines for construction projects that provide recommendations for the air quality environment during construction. The Canada Green Building Council makes the following recommendations for installations:

- Architectural woodwork: relative humidity 43-70 per cent

- Gypsum board: 13 to 21 C, relative humidity under 55 per cent

- Resilient rubber sheet flooring: over 21 C, relative humidity under 75 per cent

- Resilient sheet safety flooring: over 20 C, relative humidity under 75 per cent

- Resilient strip flooring: 21 C or higher, relative humidity under 75 per cent

- Resilient base: over 20 C, relative humidity per manufacturer’s requirements

- Epoxy seamless flooring: over 20 C, relative humidity under 75 per cent

- Carpet tile: temperature per manufacturer’s requirements, relative humidity under 75 per cent

The requirements of modern construction and industrial processes, as well as more stringent indoor air quality standards, have resulted in an increased demand for effective control of both industrial and commercial indoor spaces. ASHRAE Standard 62-1989, for instance, states, “Relative humidity in habitable spaces preferably should be maintained between 30 and 60 per cent to minimize growth of allergenic and pathogenic organisms.” (Section 5.11).

|

|

|

|

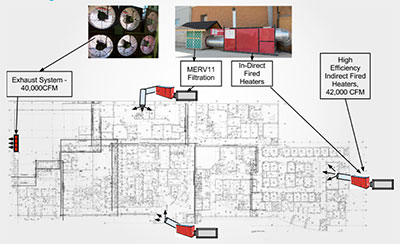

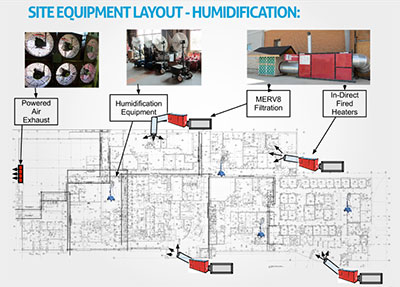

| These site layouts show the difference between two indoor air quality solutions. On the left is a typical layout for heating a building interior. On the right, a dehumidification setup.

|

There are high-efficiency temporary air-quality systems available on the market that offer numerous advantages when it comes to controlling temperature, humidity, and air quality. A specific, tailored strategy needs to be established based on the customer’s project details and location. The benchmark for the IAQ control goals should be based on the specifications of the future building’s permanent systems. The temporary system’s design should be effective enough to maintain constant control, with minimal fluctuations. When choosing air-quality equipment, look for a supplier with real life experiences and testing that translates into techniques that are field-proven with data to support their value in the field. For instance, at Cavalier, we have documented proof that we have improved product quality by means of reducing casework and millwork rejected from construction sites and increased schedule efficiency by reducing drying times for drywall taping and other curing products, as well as mitigating shrinkage and expansion problems for drywall and flooring. From staff productivity to air quality after owner occupancy, all areas of the project benefit from improved site air quality.

We have outlined several techniques that have been tested and proven successful with the recent completion of multiple test pilot projects. In each case, optimal curing environments ensured the construction schedule remained intact, building deficiencies were very low and staff productivity was increased. For temperature control we recommend an indirect-fired heating system using air-to-air or glycol and cooling systems using a chiller or an air-cooled industrial system. Dehumidification requires refrigerant or desiccant systems, and for humidification you should prefer high-pressure misting systems or steam. To improve air quality, HEPA filter the air using HEPA filter ducts with construction air barriers and HEPA filter boxes.

Make sure the equipment you select provides real solutions to all of the above areas. Remember, requirements can vary dramatically by region. The IAQ strategy for Vancouver is entirely different from Toronto. The fact is, if you review regional weather history across Canada, you won’t find a single area that is room temperature and 35 to 50 per cent humidity at any time of the year. Your air-quality equipment provider should be able to implement a program at your regional level to control all of these factors.

By controlling the construction environment in line with the permanent building specification, the building materials cure in a proper manner. Changes in humidity and temperature during the curing process result in expansion and contraction of building materials, which can cause deficiencies in the building’s finish. High-end finishes such as millwork, flooring and wood cabinetry can be highly affected by temperature and humidity swings. Joint compound drying time can vary from as long as three to five days at high humidity and low temperature, to as fast as two hours at lower humidity and higher temperatures. Obviously, the difference between five days and two hours is going to have a significant impact on your customer’s bottom line. If you can illustrate the impact of IAQ on your customer’s project, you could talk yourself into a lucrative rental.

Hospitals have documented that infection control during the construction process is necessary to reduce the risk of infection to patients after the project is complete. HEPA filters can be used to create negative air barriers in line with CSA Z319 specifications, either to protect active areas of the hospitals that need to be re-modeled, or to filter exhaust air to hospital add-ons. An excellent practice with HEPA filters is to attach them to duct work during the entire construction process.

Because the air is filtered to 99.997 per cent, there is no risk of contamination. Because the system circulates filtered air, the amount of time for duct cleaning at the end of the project is drastically reduced. Air distribution throughout the structure is also improved as filtered air is moved through the permanent ducting system.

It should be noted that forced mechanical ventilation has positive effects on IAQ. By forcing a portion of outside air your customer can maintain a positive pressure within the control area. This translates into increased surface temperatures, high air quality, and better air movement within the structure. However, only a portion of outside air should be used: one to two air changes per hour.

Cavalier Industries has developed significant expertise in IAQ over numerous projects. To get help engineering an IAQ project for your customer, go to cavalierind.com and open our IAQ white paper in the Applications section. Fill out the worksheet and submit – one of our engineers will be in touch.

Talk to your contractor customers about indoor air quality when they come in to rent other equipment. You could find additional opportunities, and your customers will appreciate the benefit to their projects.

Print this page

Leave a Reply