Make-up v.s recirculating: two approaches to construction heat ventilation

By Gal Power

Features Tech tips education technologyWhen building your heat fleet it is a good idea to have a mix of different heater styles to meet any application your customers may encounter. One consideration is whether your heaters use a “make-up” air or a recirculating air supply. There are some significant differences between the two and where each is best used.

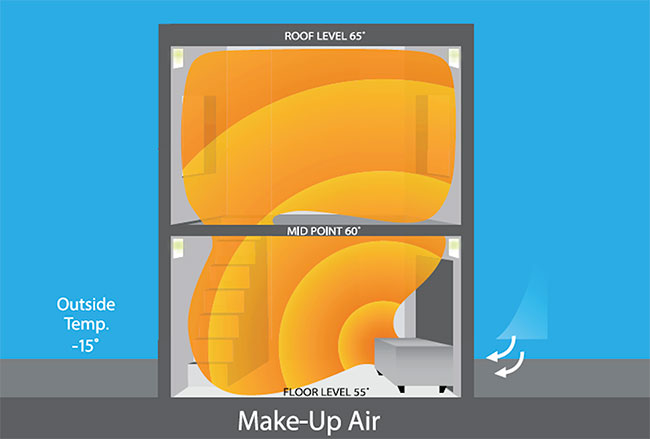

WHAT IS MAKE-UP AIR?

Make-up air is air from the outdoors that is heated and then evenly distributed indoors in a controlled manner. This drier, tempered, fresh air has the ability to absorb moisture and diffuse the fumes from the construction process by replacing the contaminated air in the building with fresh air. It provides lower relative humidity levels and dew point temperatures inside the building to prevent condensation and minimize the potential for mould.

What are recirculating heaters?

Recirculated air heaters are indirect-fired units that come in a variety of types and sizes. They can use diesel fuel, natural gas or propane. Recirculating units use their fuel to power a heat exchanger, rather than directly heating the air, and the combustion process is fully contained and the exhaust is vented back outside.

WHAT ARE THE ADVANTAGES OF USING MAKE-UP AIR UNITS?

Make-up air heat is better for curing and drying wet building materials such as drywall, concrete, paint and adhesives. Ordinary recirculation does not remove moisture from the building. As existing moisture evaporates from construction materials, it stays in the air and is simply recirculated through the heating process. Buildings that are heated via recirculation typically have a higher relative humidity, which can extend drying times. Because make-up air units are constantly introducing fresh outside air, the evaporated moisture is forced out of the building by the new dry air coming in. Outside air in the winter typically has a very low relative humidity, however, this is always dependent on location.

When to use RECIRCULATING HEATERS

Perhaps the biggest advantage of recirculating heaters is that they can be used to heat occupied buildings. It is important to note that make-up air units cannot be used in an occupied building and are for use during construction only. Diesel fuel is not available in make-up air applications, so if that is the only fuel available on site, recirculating or indirect-fired heaters need to be used. A recirculating heater attempts to control the temperature issue only. It does add moisture from the combustion process and relies on uncontrolled infiltration to ventilate. Recirculating heaters can potentially save on fuel consumption. Depending on the unit, they can also be used to duct the heated air to remote locations to heat colder spots.

WHAT ABOUT SET UP?

As make-up air units typically offer more BTUs and CFMs per unit, you usually need fewer units on a site. As a result, the installation costs are often lower. There may also be savings because your staff is maintaining less units over the long term.

All buildings infiltrate, or “breathe.” This naturally occurring air movement happens when there is a temperature difference between the inside and the outside air. Because buildings breathe, and because there are air contaminants (paint, adhesives, exhaust gases, etc.) and moisture during construction that needs to be diffused or exhausted, it is desirable to mechanically control the process through the heater. Make-up air heaters allow the introduction of controlled amounts of fresh, tempered air from the outside.

When using a make-up air unit, it is desirable to seal up the building as much as possible to avoid normal infiltration through doors and windows. The more a building is sealed, the better the heat retention, and this applies for all types of heat. However, some of the largest benefits of using make-up air will occur in a loosely sealed building as the building’s pressurization, via the make-up air unit, essentially moves interior air outwards continually and exhausts it while keeping the outside elements out. This is where make-up air units excel at keeping even heat distribution even in the largest and densest of buildings.

As you can see, the choice between make-up air heat and recirculating heat can be complex. Is drying the goal, or simply heating the workspace? What is the outdoor humidity? Is the building occupied? What fuel sources are available? How much ducting is required? The answers to all these questions will determine the right choice for your customer.

GAL Power offers specialized power and temperature control solutions from nine locations across Ontario and Quebec.

Print this page

Leave a Reply