Tech Tips: Rammer engine maintenance

By Brad Murphy vice-president sales and marketing Subaru Industrial Power Products

Features Tech tipsLife in the rental yard isn’t easy. Going from rental centre to jobsite, being thrown from one equipment trailer to another and working long days, all while receiving little care and preventive maintenance along the way. Yes, it can be a tough life.

Life in the rental yard isn’t easy. Going from rental centre to jobsite, being thrown from one equipment trailer to another and working long days, all while receiving little care and preventive maintenance along the way. Yes, it can be a tough life.

|

|

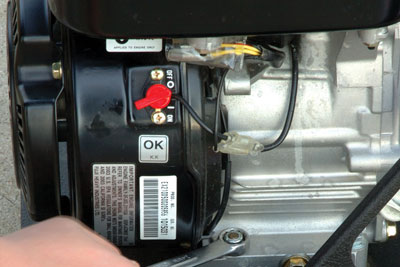

| Inspect the engine regularly and tighten any loose bolts that could vibrate excessively and damage other parts and components.

|

While all construction equipment works hard, rammers face one of the most demanding applications in the construction industry. And if the rammer has it tough, imagine what the engine goes through. The repetitive up-and-down motion and constant vibrating and shaking these engines endure on a daily basis can wreak havoc on their lives – not to mention the dusty, dirty work environment. Yet they are always expected to start with one pull.

All rental customers essentially want the same thing: a piece of equipment that will work well throughout the entire duration of the job. And good customer service means delivering on the promise of providing quality equipment, making it crucial for rental-house operators to properly care for and maintain every piece of equipment coming and going.

By investing the time to perform basic, routine, engine maintenance, rental-centre operators can ensure every rammer going out the door will provide reliable, quality performance, bringing back a return on investment and a satisfied customer. Engines require a variety of maintenance throughout the year, both daily and less frequent. The following are the top five attention areas for a basic engine maintenance program.

Obligation to oil

|

|

| When checking the engine oil, be sure the dipstick is clear of any dust, dirt or debris that could harm the engine. This is especially important for rammer engines, as they operate in very dusty environments. |

Oil is one of the keys to the service life of an engine, and daily attention is a must. Many rental-centre operators have heard this fact, yet neglect to remind operators of the importance of checking the oil before each use. But reminding rental customers that this small time investment will reap huge performance rewards may entice them to put it on their daily to-do list.

Beyond daily level and quantity checks, oil needs bimonthly attention as well. In typical applications, engine oil should be changed every 100 hours to remove potentially harmful sludge. But in the case of especially dusty and dirty environments, like rammer applications, the oil should be changed more frequently. Rental-centre operators should make it a habit to give the engine a fresh oil change each time a rammer comes back.

Air care

Along with oil, the air filter is one of the most important factors in promoting peak performance and long service life.

Checking the condition of the air filter daily can prevent significant engine damage and will take just minutes from the customer’s day. A clogged, wet or damaged air filter can lead to a loss in efficiency and power, or it might cause an engine to shut down altogether, causing the operator to waste time troubleshooting. Even worse, a neglected filter may shorten the life of an engine by allowing dirt or water into sensitive areas.

Cleaning a paper filter is quick and easy. Simply remove it and tap it on a hard surface to knock off excess dirt. Do not use compressed air to clean the filter elements, as this may cause tears in the paper. While manufacturers typically recommend replacing paper filters after about 50 hours of use, rammer applications will require more frequent replacements to address the excess dust and dirt that go along with the work environment. Making it a point to check the filter regularly ensures a replacement is made when it is actually needed.

Clean and inspect

Another daily maintenance step is one of the most basic – cleaning the engine. Not only does it get rid of potentially harmful dirt, a clean engine provides a great way for a rental-centre operator to quickly check the engine for leaks, loose parts and damaged components.

Prior to cleaning at the end of a workday, instruct customers to first shut down the rammer and allow it ample cooling time before cleaning the engine. Cold water coming into contact with a hot engine may cause cracks and damage, not to mention the risk of receiving severe burns from touching hot engine parts.

Clean a greasy or dirty engine by spraying it with a non-petroleum-based degreaser. Wait for the solvent to start breaking down the dirt, then wipe it clean with a cloth or soft brush. Warm water at a low pressure can be used to rinse the engine. Dry the outside immediately afterward, and run the engine for a few minutes to help dry any parts that could not be easily dried with a cloth.

Though it may seem like a convenient option, never use a pressure washer to clean an engine. The pressure could be enough to break through the engine seals, resulting in water in the engine. And even if the engine is not hot, cold water can still cause cracks or damage.

When the engine is clean, it can be thoroughly inspected. Anything that is damaged should be replaced, and any loose parts that could vibrate and potentially harm nearby components should be tightened. Aside from regular, frequent inspections, every rental-centre operator should inspect the engine for dirty, broken and misaligned parts on an annual basis. Such parts can cause a variety of engine problems, and thoroughly inspecting the engine gives the most comprehensive view of what needs to be cleaned and repaired.

Fundamentals of fuel

In addition to inspecting the clean engine for damaged parts, be on the lookout for any signs of fuel leakage. If a leak is detected, tighten the parts causing the leak or replace them immediately. Failing to fix the leak is wasteful, inefficient, environmentally irresponsible and also potentially dangerous.

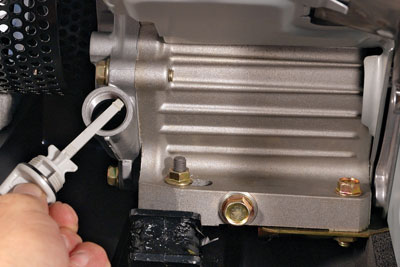

Additionally, it is important to clean and inspect the fuel strainer and fuel filter every month, even a bit more frequently if the rammer has been especially active. Contaminated fuel that is not removed can lead to trouble with engine starts. Replacing the fuel line and carburetor is expensive and time-consuming, so it is essential to prevent unnecessary damage caused by contaminated fuel.

If there is sediment on the fuel strainer, shut off the fuel line valve before any maintenance or cleaning. Then, remove, empty and clean the sediment bowl and clean the filter screen. If sediment has gone into the tank, all the fuel will need to be removed. Clean the residue from the sediment reservoir, which is the lowest point in the tank. Use a clean rag to wipe sediment from the filter element and the sides of the tank before refilling the tank with clean fuel.

Finally, when performing the annual inspection, check the fuel hose and replace it if there are cracks.

Spark some interest

|

|

| Check the engine’s spark plugs for damage, dirt and excessive carbon buildup, and clean or replace as needed.

|

The final basic maintenance item, though not a daily task, is to check the engine’s spark plugs every 50 hours for damage, dirt and excessive carbon build-up. Dirty spark plugs can cause a decrease in power and poor starting performance. Clean spark plugs coated with a considerable amount of dirt or carbon buildup with a wire brush or spark plug cleaner. And replace any spark plugs with cracked porcelain immediately.

Understanding maintenance specific to dusty, outdoor jobsites will help prevent problems that may be specific to tough rammer applications. Following appropriate maintenance recommendations will ensure a long engine life and preserve the rammer’s power and performance. Best of all, a little time investment to a basic routine maintenance program will pay back big time. The less time an engine spends in the shop for major repairs or overhaul, the more time it has to be rented out, providing high returns on investment and a happy, repeat customer.

Brad Murphy is vice-president of sales and marketing for Subaru Industrial Power Products, and an expert on small, air-cooled engine maintenance. For more information, feel free to contact Murphy at 847-847-2970 or bmurphy@robinamerica.com.

Print this page