The reliability of gas with the sustainability of electric comes together in these cutting-edge hybrid power options.

One week on a tank

genielift.com

Two machines in one, the Genie Z-60 FE hybrid articulating boom lift is an environment-friendly solution for increased efficiency and low cost of operation. In all-electric mode it offers a full work day of emissions-free run time on a single battery charge. In hybrid mode, it offers one week of run time with a single tank of diesel. The full-time-active oscillating axle helps maintain traction on rough terrain. Four-wheel-drive and 45 percent gradeability allows access to all terrain. The Z-60 features a high-efficiency AC drive system for enhanced driving performance and simplified maintenance. Dual parallelogram and fully proportional controls deliver precise boom positioning and smooth performance. A five-foot articulating jib with a 135-degree vertical rotation accurately positions workers. the Genie Fast Mast boom system allows operators to descend and retrieve materials and quickly return to working height.

Increased productivity

komatsu.com

The Komatsu HB365LC-3 hybrid hydraulic excavator is powered by a Komatsu SAA6D114E-6 Tier 4 Final engine and a Komatsu hybrid electrical swing system that provides plenty of torque and acceleration for all excavating tasks, helping increase productivity while promoting carbon reduction. Compared to Komatsu non-hybrid excavators in the same class, the HB365LC-11 can help increase productivity by up to 15 percent; reduce fuel consumption by up to 20 percent depending on application; and lessen carbon dioxide emissions. The engine produces 269 horsepower at 1,950 RPM. Operating weight is 81,791 to 85,495 pounds and bucket capacity is 0.89 to 2.56 cubic yards. The HB365LC-3 features a powerful, responsive swing system with improved swing acceleration that helps improve cycle times. Whether on the slopes or in the trenches, this machine is suitable for applications such as bulk material handling; loading crushers and concrete recycling; truck loading with 90-degree swing angles; and typical trenching when depth is less than 12 feet. Fuel consumption is reduced with the hybrid energy conservation system; Tier 4 Final engine technology; an ultra-low idle speed; and a viscous fan clutch. The HB365LC-3 features high production and performance with two-mode boom settings; an electrically driven swing motor; six working modes for a wide variety of applications; and lifting mode for increased capacity. It sports comfortable operation with a spacious, climate-controlled, rollover-protected cab; high-back air-suspension seats with heat; a low-vibration cab damper mounting; a pressurized cabin with an air filter and automatic climate control.

The Komatsu HB365LC-3 hybrid hydraulic excavator is powered by a Komatsu SAA6D114E-6 Tier 4 Final engine and a Komatsu hybrid electrical swing system that provides plenty of torque and acceleration for all excavating tasks, helping increase productivity while promoting carbon reduction. Compared to Komatsu non-hybrid excavators in the same class, the HB365LC-11 can help increase productivity by up to 15 percent; reduce fuel consumption by up to 20 percent depending on application; and lessen carbon dioxide emissions. The engine produces 269 horsepower at 1,950 RPM. Operating weight is 81,791 to 85,495 pounds and bucket capacity is 0.89 to 2.56 cubic yards. The HB365LC-3 features a powerful, responsive swing system with improved swing acceleration that helps improve cycle times. Whether on the slopes or in the trenches, this machine is suitable for applications such as bulk material handling; loading crushers and concrete recycling; truck loading with 90-degree swing angles; and typical trenching when depth is less than 12 feet. Fuel consumption is reduced with the hybrid energy conservation system; Tier 4 Final engine technology; an ultra-low idle speed; and a viscous fan clutch. The HB365LC-3 features high production and performance with two-mode boom settings; an electrically driven swing motor; six working modes for a wide variety of applications; and lifting mode for increased capacity. It sports comfortable operation with a spacious, climate-controlled, rollover-protected cab; high-back air-suspension seats with heat; a low-vibration cab damper mounting; a pressurized cabin with an air filter and automatic climate control.

Long engine life

deere.com

The 944 X-Tier wheel loader from John Deere produces 536 horsepower at 1,600 RPM with an operating weight of 119,607 to 124,614 pounds and a bucket capacity of 8.5 to 10 cubic yards. The hybrid-electric drivetrain consists of the John Deere 13.5-litre engine, a gearbox, two three-phase AC permanent magnet generators, power electronics or inverters, four three-phase AC switched reluctance motors, four two-stage reduction final drives and two brake resistors. The engine operates at either a limited engine speed range or at constant speed, like a generator set, and connects to a gearbox which houses the hydraulic pumps. The gearbox then transfers engine power to the electric generators and the hydraulic pumps. The electric generators convert rotational energy from the engine into three-phase alternating current electrical energy. From here the power electronics, or inverter, delivers this electrical energy from the generators to the electric motors based on operator demand. The electrical motors convert the three-phase alternating current back to rotational energy and torque into the final drives. Excess energy is passively consumed through two brake resistors that assist in maintaining reversal performance and engine over speed while coasting downhill. Engines that can be run at constant speed like a generator set typically have very long life when operating over a limited speed range. When the operator lays off the accelerator pedal, changes direction, or when the loader is driven downhill, inertia and gravity can continue to drive the loader. When this happens, the electric motors are being mechanically driven by the wheels through the driveline and temporarily become generators, adding supplemental energy to the electric drive system. This recovered energy is sent to the power electronics which can in turn now use this energy to drive the generators to assist with driving the hydraulic pumps, reducing the load on the engine and allowing the engine controller to send less fuel to the engine, which is where the gains in fuel economy become very evident. The power electronics is able to constantly monitor all the energy in the system and helps determine the most efficient path for this energy to go. Recycled energy cannot be stored by the electric drive system but there is a system in place that allows the excess energy to be consumed in the form of the two brake resistors that consume extra energy and assist in braking, limiting the amount of mechanical braking needed which in turn reduces brake wear and lowers maintenance costs

The 944 X-Tier wheel loader from John Deere produces 536 horsepower at 1,600 RPM with an operating weight of 119,607 to 124,614 pounds and a bucket capacity of 8.5 to 10 cubic yards. The hybrid-electric drivetrain consists of the John Deere 13.5-litre engine, a gearbox, two three-phase AC permanent magnet generators, power electronics or inverters, four three-phase AC switched reluctance motors, four two-stage reduction final drives and two brake resistors. The engine operates at either a limited engine speed range or at constant speed, like a generator set, and connects to a gearbox which houses the hydraulic pumps. The gearbox then transfers engine power to the electric generators and the hydraulic pumps. The electric generators convert rotational energy from the engine into three-phase alternating current electrical energy. From here the power electronics, or inverter, delivers this electrical energy from the generators to the electric motors based on operator demand. The electrical motors convert the three-phase alternating current back to rotational energy and torque into the final drives. Excess energy is passively consumed through two brake resistors that assist in maintaining reversal performance and engine over speed while coasting downhill. Engines that can be run at constant speed like a generator set typically have very long life when operating over a limited speed range. When the operator lays off the accelerator pedal, changes direction, or when the loader is driven downhill, inertia and gravity can continue to drive the loader. When this happens, the electric motors are being mechanically driven by the wheels through the driveline and temporarily become generators, adding supplemental energy to the electric drive system. This recovered energy is sent to the power electronics which can in turn now use this energy to drive the generators to assist with driving the hydraulic pumps, reducing the load on the engine and allowing the engine controller to send less fuel to the engine, which is where the gains in fuel economy become very evident. The power electronics is able to constantly monitor all the energy in the system and helps determine the most efficient path for this energy to go. Recycled energy cannot be stored by the electric drive system but there is a system in place that allows the excess energy to be consumed in the form of the two brake resistors that consume extra energy and assist in braking, limiting the amount of mechanical braking needed which in turn reduces brake wear and lowers maintenance costs

Extra stability

sanyamerica.com

The SET240S from Sany has a load weight of 220 tons, producing maximum torque of 3,000 newton meters and 2,090 kilowatts power. The performance of drive system depends on the gross vehicle weight, gradient and length of the transport road including rolling resistance, engine power, and other parameters. The drive system can adjust to the actual working conditions to realize the optimal performance of the mining dump truck. Features include independent hydraulic steering with a closed-centre steering valve, a pressure compensating piston pump and an accumulator. The accumulator provides uniform steering regardless of the engine speed. In the event of a loss of engine power, it provides emergency power to the system for steering.The SET240S has independent front suspension. The smaller swing arm motion reduces the lateral displacement of the tires and prolongs their lives for extended life and maintenance periods. Dual variable-section box structures welded from high-strength alloy steel plates and steel castings are integrated with the rollover protection structures to achieve excellent bending capacity, strong distortion resistance, enduring impact ductility and extended life. There are independent hydraulic systems with retarders at limiting positions. Two three-section hoist cylinders are mounted on both sides of the frame rails to keep the body stable while raising. The cab is equipped with an integral four-pillar tipping protection design, an adjustable cushioned seat, luxury upholstery and a tiltable and telescopic steering wheel to provide a comfortable operating space, conforming to ISO 3471. The cab provides an equivalent sound level of less than 78 decibels when tested with doors and windows closed.

The SET240S from Sany has a load weight of 220 tons, producing maximum torque of 3,000 newton meters and 2,090 kilowatts power. The performance of drive system depends on the gross vehicle weight, gradient and length of the transport road including rolling resistance, engine power, and other parameters. The drive system can adjust to the actual working conditions to realize the optimal performance of the mining dump truck. Features include independent hydraulic steering with a closed-centre steering valve, a pressure compensating piston pump and an accumulator. The accumulator provides uniform steering regardless of the engine speed. In the event of a loss of engine power, it provides emergency power to the system for steering.The SET240S has independent front suspension. The smaller swing arm motion reduces the lateral displacement of the tires and prolongs their lives for extended life and maintenance periods. Dual variable-section box structures welded from high-strength alloy steel plates and steel castings are integrated with the rollover protection structures to achieve excellent bending capacity, strong distortion resistance, enduring impact ductility and extended life. There are independent hydraulic systems with retarders at limiting positions. Two three-section hoist cylinders are mounted on both sides of the frame rails to keep the body stable while raising. The cab is equipped with an integral four-pillar tipping protection design, an adjustable cushioned seat, luxury upholstery and a tiltable and telescopic steering wheel to provide a comfortable operating space, conforming to ISO 3471. The cab provides an equivalent sound level of less than 78 decibels when tested with doors and windows closed.

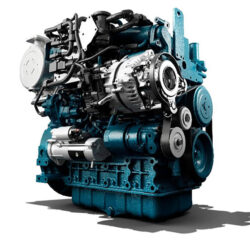

Easy to retrofit

kubotaengine.com

Kubota Engine America’s V3307 Micro-Hybrid Engine provides power assistance during peak performance, using electric power to compensate for high loads instantaneously. For some applications, high load is required for only a fraction of the total work time. The engine’s 10-kW electric motor-assist function allows customers to match those high load demands and select an engine with an output power tailored to the low and medium load regions of frequent use.

Kubota Engine America’s V3307 Micro-Hybrid Engine provides power assistance during peak performance, using electric power to compensate for high loads instantaneously. For some applications, high load is required for only a fraction of the total work time. The engine’s 10-kW electric motor-assist function allows customers to match those high load demands and select an engine with an output power tailored to the low and medium load regions of frequent use.

In addition, machinery already equipped with a Kubota engine can leverage this Micro-Hybrid technology by installing three main components. This allows customers to enhance the added value of their existing applications with a minimal development cost. Kubota’s Micro-Hybrid Engine stresses its minimal implementation, making the engine a simple, easy-to-install system. The engine has a straightforward design with three main components: a DC converter, a lithium-ion battery and a motor generator attached to the existing engine model. In addition, the Hybrid system is controlled by the engine control unit, not big signals from the vehicle. This is made possible by rewriting the software in the existing ECU, only available to Kubota engines. No additional ECU is required for Hybrid control. The engine is equipped with a 48-volt motor generator, providing high torque with quick response, boosting overall work efficiency. At low speeds, the motor provides up to 70 newton meters of torque assistance. Designed for applications that demand an immediate response to instantaneous peak overloads within the typical machine duty cycle, the power assist Micro-Hybrid system supports the engine by delivering an additional electrical power boost of up to 10 kilowatts. The instant-available torque offers an efficiency boost at the most crucial time, while recuperating and recharging its battery pack when not initiated. These innovations push the boundaries in areas of fuel efficiency, power density and adaptability. Kubota’s Micro-Hybrid Engine technology will fit compactly in the mounting space with no selective catalytic reduction required for diesel engines with output of 56 kilowatts or more. Eliminating the need for SCR saves on time needed to top up diesel exhaust fluid. It saves maintenance work and eliminates the running cost of DEF. In addition, the motor-assist function can also be expected to help reduce fuel consumption. The Kubota Micro-Hybrid Engine complies with EPA/CARB Tier 4 and State V emission regulations.

Conquers rough terrain

kobelco-usa.com

The Kobelco hybrid system has further evolved with the introduction of the SK210HLC-10. The new electric swing motor combined with the additional hybrid components are optimized for efficiency without sacrificing productivity. During heavy digging, the motor/generator/lithium-ion battery assists the engine and hydraulic pump in order to reduce fuel consumption and engine exhaust emissions. The components of the hybrid system work in harmony with the same size engine as a conventional SK210LC-10, making the machine even faster for increased cycle times. While the machine is digging or swinging, an assist from the generator motor greatly reduces the engine load and generates extra power. The stored electrical power in the lithium-ion battery now flows back to the motor/generator to assist the engine to power the hydraulic functions. Reducing the power demand on the diesel engine, it reduces fuel flow and thereby increases overall efficiency. The braking energy generated during swing deceleration is converted into electrical energy and then the electricity is accumulated in the lithium-ion battery The unused energy of the lightly loaded engine is used to generate electrical power and recharge the lithium-ion battery to full stand-by level. The higher power capacity of the lithium-ion battery provides longer, more consistent, engine assist power and independent swing. Maximum bucket digging force with the power boost is 35,300 pounds. The maximum arm crowding force with power boost is 25,200 pounds. The drawbar pulling force is 51,000 pounds, delivering the capacity to conquer rough terrain and slopes.

The Kobelco hybrid system has further evolved with the introduction of the SK210HLC-10. The new electric swing motor combined with the additional hybrid components are optimized for efficiency without sacrificing productivity. During heavy digging, the motor/generator/lithium-ion battery assists the engine and hydraulic pump in order to reduce fuel consumption and engine exhaust emissions. The components of the hybrid system work in harmony with the same size engine as a conventional SK210LC-10, making the machine even faster for increased cycle times. While the machine is digging or swinging, an assist from the generator motor greatly reduces the engine load and generates extra power. The stored electrical power in the lithium-ion battery now flows back to the motor/generator to assist the engine to power the hydraulic functions. Reducing the power demand on the diesel engine, it reduces fuel flow and thereby increases overall efficiency. The braking energy generated during swing deceleration is converted into electrical energy and then the electricity is accumulated in the lithium-ion battery The unused energy of the lightly loaded engine is used to generate electrical power and recharge the lithium-ion battery to full stand-by level. The higher power capacity of the lithium-ion battery provides longer, more consistent, engine assist power and independent swing. Maximum bucket digging force with the power boost is 35,300 pounds. The maximum arm crowding force with power boost is 25,200 pounds. The drawbar pulling force is 51,000 pounds, delivering the capacity to conquer rough terrain and slopes.

LIGHTER AND MORE COMPACT

kohlerenergy.com

The Kohler K-HEM 1003 generates power using a combination of a KDW 1003 18-kilowatt diesel engine (compliant with Stage V standards and without DPF) and a 48-volt electric engine that guarantees 15 kilowatts of peak power and nine kilowatts of continuous power. This means that the unit is capable of providing over 30 kilowatts without the need for exhaust-gas aftertreatment systems. What’s more, K-HEM can operate as a generator for energy accumulation systems. The K-HEM hybrid unit has been designed to satisfy the needs of all types of equipment that are distinguished by intermittent duty operation cycles that call for power peaks (welders, mowers, tractors with implements, etc.) and machines that chiefly run continuous low load operation cycles, which prevent them from reaching the temperatures necessary for passive regeneration to occur inside the particulate filter (aerial platforms, forklifts, etc.). With K-HEM, the power base is provided by the combustion engine, while the power peaks are guaranteed by the electric engine. This system, which complies with the limits laid down in Stage V standards, makes it possible for machines to avoid underating and guarantees high productivity levels. The built-in master control unit allows users to monitor and manage working modes and transitions based on their needs. All of this translates into lighter, more compact and better-performing machines than in the past, capable of exploiting all of the benefits arising from the integration of mechanical power and electric power: less complex engines; an absence of aftertreatment systems; the ability to store and use excess energy produced thanks to the built-in alternator; energy recovery during braking and exhaust phases; the ability to manage operations using the master control unit; reduction of gas emission, noise and consumption rates; improved performance and power modulation, thanks to the integrated management of each operation.

The Kohler K-HEM 1003 generates power using a combination of a KDW 1003 18-kilowatt diesel engine (compliant with Stage V standards and without DPF) and a 48-volt electric engine that guarantees 15 kilowatts of peak power and nine kilowatts of continuous power. This means that the unit is capable of providing over 30 kilowatts without the need for exhaust-gas aftertreatment systems. What’s more, K-HEM can operate as a generator for energy accumulation systems. The K-HEM hybrid unit has been designed to satisfy the needs of all types of equipment that are distinguished by intermittent duty operation cycles that call for power peaks (welders, mowers, tractors with implements, etc.) and machines that chiefly run continuous low load operation cycles, which prevent them from reaching the temperatures necessary for passive regeneration to occur inside the particulate filter (aerial platforms, forklifts, etc.). With K-HEM, the power base is provided by the combustion engine, while the power peaks are guaranteed by the electric engine. This system, which complies with the limits laid down in Stage V standards, makes it possible for machines to avoid underating and guarantees high productivity levels. The built-in master control unit allows users to monitor and manage working modes and transitions based on their needs. All of this translates into lighter, more compact and better-performing machines than in the past, capable of exploiting all of the benefits arising from the integration of mechanical power and electric power: less complex engines; an absence of aftertreatment systems; the ability to store and use excess energy produced thanks to the built-in alternator; energy recovery during braking and exhaust phases; the ability to manage operations using the master control unit; reduction of gas emission, noise and consumption rates; improved performance and power modulation, thanks to the integrated management of each operation.

Exceptional terrainability

jlg.com

The H340AJ hybrid articulating boom lift from JLG features a platform height of 33 feet, 10 inches and a machine width of six feet, four inches. It delivers diesel-like performance with four independent electric-drive motors and a Tier 4 Final diesel-powered generator for exceptional terrainability. It runs completely on eight 12-volt 100-amp-hour AGM batteries, which are charged by the diesel generator. The power of a diesel machine combined with its hybrid efficiency allows customers to work both inside and outside. The H340Aj offers reduced fuel use, emissions, noise and maintenance compared to a diesel-powered JLG 340AJ under similar test conditions. It comes with a standard LED motion/amber beacon and ClearSky Smart Fleet connectivity hardware.

The H340AJ hybrid articulating boom lift from JLG features a platform height of 33 feet, 10 inches and a machine width of six feet, four inches. It delivers diesel-like performance with four independent electric-drive motors and a Tier 4 Final diesel-powered generator for exceptional terrainability. It runs completely on eight 12-volt 100-amp-hour AGM batteries, which are charged by the diesel generator. The power of a diesel machine combined with its hybrid efficiency allows customers to work both inside and outside. The H340Aj offers reduced fuel use, emissions, noise and maintenance compared to a diesel-powered JLG 340AJ under similar test conditions. It comes with a standard LED motion/amber beacon and ClearSky Smart Fleet connectivity hardware.

Print this page

Leave a Reply