Careful with the nasty stuff

By James Hong

Features Government and regulatoryKnow the rules for storing, transporting and handling hazardous materials.

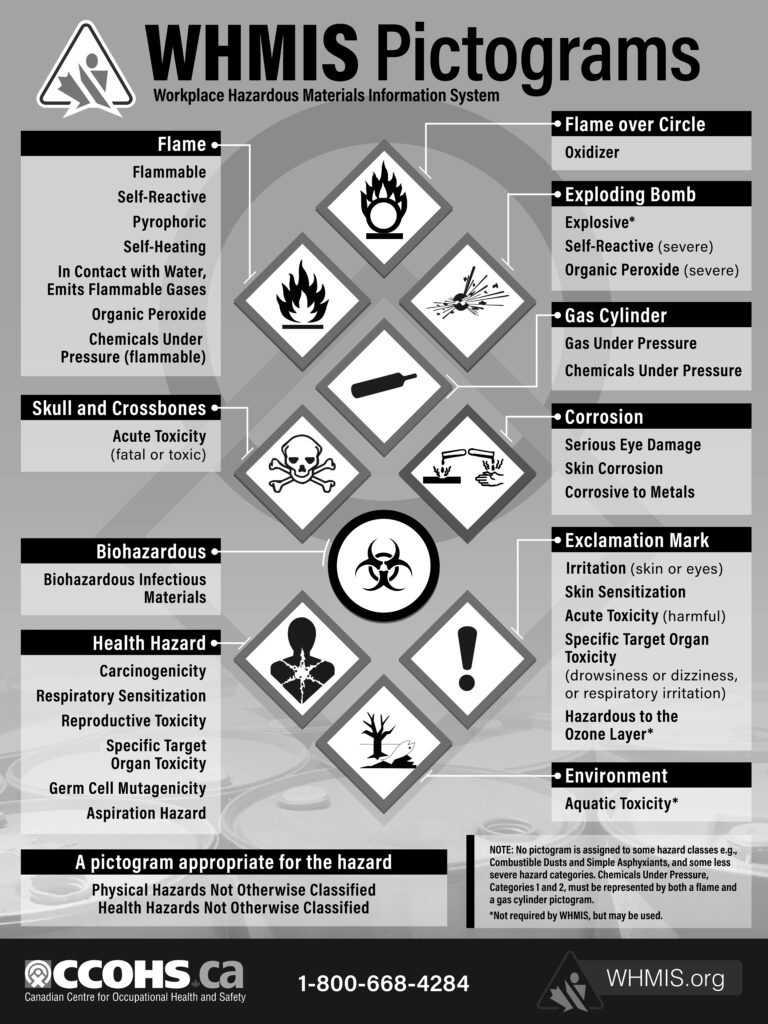

WHMIS Pictorial, Canadian Centre for Occupational Health and Safety (CCOHS), 2015. Reproduced with the permission of CCOHS, 2024

WHMIS Pictorial, Canadian Centre for Occupational Health and Safety (CCOHS), 2015. Reproduced with the permission of CCOHS, 2024 Hazardous materials encompass a wide range of substances that due to their physical or chemical properties pose a risk to people, property or the environment. This includes chemicals and gases that are flammable, radioactive or otherwise toxic.

The Globally Harmonized System of Classification and Labelling of Chemicals is a comprehensive set of international guidelines developed by the United Nations to protect against the danger of exposure to chemicals. The goal is to communicate the danger of chemical exposure in many different languages and social conditions, including to illiterates. It’s international classification and labelling system is the foundation of the GHS. This system of communication defines the classification of chemicals by types of hazard and hazard communication elements, including labels and safety data sheets. Identifying and understanding the health, physical, and environmental hazards posed by specific chemicals is possible by providing critical information for ensuring proper handling, storage and disposal practices.

WHMIS

The Workplace Hazardous Materials Information System (WHMIS), on the other hand, is a Canadian system that was in place prior to the adoption of GHS. WHMIS incorporates the principles of GHS but adapts them to the specific requirements of Canadian workplace safety legislation. GHS serves as the foundation for the hazard classification and communication elements of WHMIS. Canada adopted GHS to harmonize its hazard communication system with international standards, making it easier for Canadian businesses to trade and work with hazardous materials on a global scale. While GHS provides the global framework for classifying and labeling chemicals, WHMIS adds additional requirements and elements to meet Canadian regulatory needs. This includes specific labeling and safety data sheet requirements that align with Canadian laws.

WHMIS provides information on hazardous products, as defined and described in the federal Hazardous Products Act and Hazardous Products Regulations so workers can protect themselves. WHMIS provides a means to identify chemical hazards using labels, datasheets, placards, warning signs and colour codes which alert workers to hazards and safe handling instructions.

Labels work hand-in-hand with Material Safety Data Sheets, now known as Safety Data Sheets, which are standardized documents that contain occupational safety and health information as mandated by the International Hazard Communication Standard. Safety Data Sheets were developed by the Occupational Safety and Health Administration (OSHA) in the United States. The development of SDS is traced back to the Occupational Safety and Health Act of 1970, giving OSHA the authority to develop and enforce workplace safety and health regulations. Safety Data Sheets have been developed and regulated in Canada under provincial occupational health and safety legislation. The transition from the older MSDS to SDS was done to bring Canada’s documentation into alignment with the GHS.

Safety Data Sheets are comprehensive and cover essential details such as chemical properties; potential health and environmental hazards; recommended protective measures; and safety precautions for proper storage, handling, and transportation of chemicals. SDS can be obtained from many searchable online databases by using the search terms MSDS or SDS search. Products can be found using product names, manufacturer names or product codes.

Labels

WHMIS labels are an effective means of communicating the dangers of hazardous materials using pictographs, colours and codes. One type of label is for suppliers and another type of label is for the workplace. Supplier labels should list the product name; the first aid measure in case of exposure; hazard symbols; a supplier identifier; the risk phrases reference to the SDS; and any precautionary measures users should take. Workplace label requirements include the product name, safe handling procedures and a reference to the SDS.

There are also standardized warning signs with colour, number coding and system symbols for identifying piping systems, reaction vessels, tank cars and conveyor belts carrying a controlled product. Transporting hazardous materials, whether in small or large amounts between jobs or as part of the logistics industry, is a potentially dangerous and regulated responsibility.

Types of hazardous materials

Hazardous materials are classified into different groups with the classification determining packaging, labelling, and transporting. There are nine hazard classes: explosives, gases, flammable liquids, flammable solids, oxidizing substances and organic peroxides, toxic and infectious substances, radioactive materials, corrosive substances and miscellaneous dangerous goods. Proper packaging prevents leaks, spills and reactions during transportation. The different types of packaging are drums, cylinders, or specialized containers. Clear and standardized labeling is critical information for transportation personnel, emergency responders and the public, alerting them to the potential hazards. Labels are regulated to include information on the material’s identity, hazard class and other pertinent information.

Each mode of transportation whether by road, rail, air or sea, has specific regulations and safety measures. Transportation companies and first responders must have plans in place for handling incidents involving hazardous materials such as spills, leaks, or fires. Drivers, handlers, and emergency responders, must take and graduate specific training to obtain certifications to ensure they understand the risks, necessary safety procedures and are educated in understanding labeling information, data sheet access and posting and corresponding handling requirements. The specific certification regulations vary province to province, so consult your region’s transportation authorities. Security is also an important measure to protect against theft and unauthorized access because of the potential for hazardous materials to be used for malicious purposes.

Proper containment and spill response will mitigate the potentially huge destructive environmental consequences of accidents and spills during transportation. Chemical load GPS tracking, sensors and data analytics, plays a role in monitoring and enhancing the safety of hazardous materials transportation. International border agreements and regulations for the transportation of dangerous goods are considerations when transporting internationally. Safe work practices for handling and transporting hazardous materials covers several protocols to safely guide workers.

Flammable liquids

Flammable liquids such as gasoline and other highly flammable liquids must not be carried in the passenger compartment of a vehicle and must be stored in approved containers with CSA or ULC labels.

Always check containers pre-trip for damage and properly secured caps and fittings. Transport flammable liquids in an upright position, braced and secured for protection against overturning. When transporting gasoline or other flammable liquids in a van, place the containers in the rear of the van with adequate ventilation. Remove the containers from the van immediately upon arrival at the destination. Provide a 5BC fire extinguisher in the driver’s compartment when gasoline or other flammable liquids are transported in a van. These are disposable extinguishers rated for B class liquid fuel fires and C class electrical fires. Gasoline engines should be shut off and allowed to cool before refuelling.

Propane

When transporting propane cylinders, keep them in an upright position unless they are designed for horizontal use. Store them in well-ventilated areas away from outdoor heat. Use only approved hoses and fittings to connect a cylinder to tools and equipment. When not in use, propane cylinders and hose-connected devices must not be left in trenches or other low-lying areas. Propane is heavier than air and can settle in dangerous concentrations at the bottom of trenches, manholes, vaults, basements, sumps and other below-grade areas. Use only soapy water to look for leaks in a propane cylinder or hose.

Oxygen and acetylene

When transporting oxygen and acetylene cylinders, secure them in an upright position at all times during storage, use and transportation. Cylinders should be stored in a well-ventilated area or outside with overhead protection from the weather. Protective caps must be in place when the cylinders are not in use or when they are being moved. Cylinders must be hoisted in properly rigged racks or baskets to keep them secure and upright. Do not move cylinders without first closing the valves.

When using oxygen and acetylene, wear leather gauntlet gloves. Type BC fire extinguishers must be available whenever oxyacetylene cutting is being done. Cylinders must not be placed where they may become part of an electric circuit or be inadvertently struck by a welding rod. Workers using oxyacetylene must not carry butane lighters. Oxygen or acetylene torches must not be used to blow dust from work surfaces, clothing or skin. Keep acetylene cylinders away from heat sources. The surrounding temperature must be kept below 54 C. Cylinders must not be placed where materials or equipment can strike, fall on or knock them over. Supply hoses must be protected from traffic and empty cylinders must be stored separately from full cylinders. Store acetylene cylinders separately from oxygen cylinders.

Do not use regulators, hoses or torches unless they are working properly. Use only a spark lighter to ignite torches. Never use matches or a cigarette lighter. A leaking gas cylinder must be shut off and removed to an outdoor location away from ignition sources and marked to be readily identifiable. The supplier should be notified about the defective cylinder.

And finally, as with all things safety related, the all-important task is to perform a risk assessment to evaluate the potential hazards associated with specific materials and routes. Transporting hazardous materials is a complex and highly regulated field requiring the highest commitment to safety, compliance and preparedness for the protection of people and the environment.

Be safe. Be well.

James Hong is an independent writer,

journalist and OHS consultant.

Print this page