Planning for the work ahead: How BIM helps anticipate challenges in the built environment

By Neil Doherty, chief engineer of EMEA digital products at JLG Industries

Features Business Intelligence Tech tips 3D BIM model Building Information Modeling equipment planning JLG Industries Neil DohertyHow BIM technology helps anticipate challenges in the built environment.

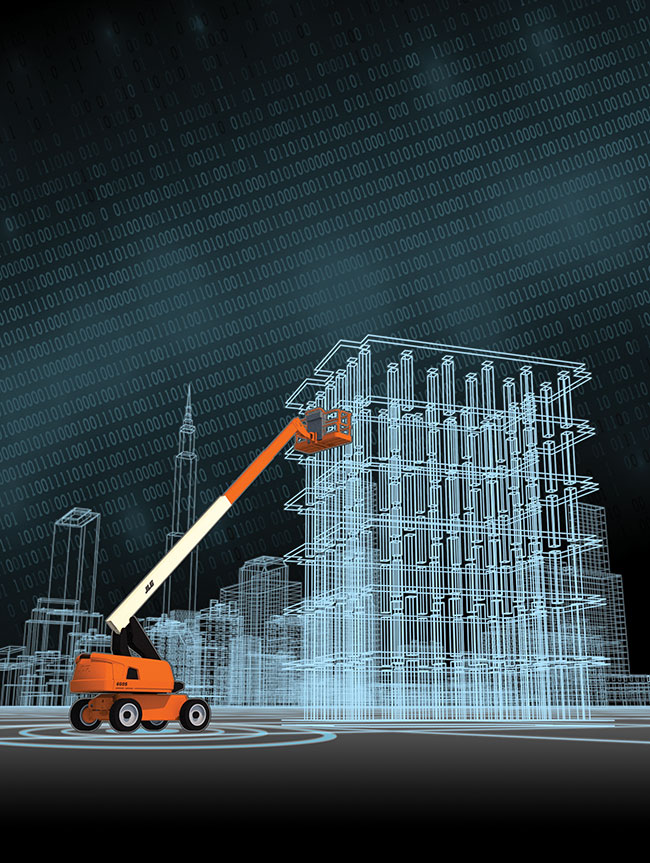

Simulating construction sites using the BIM model can help customers choose the right rental equipment.

Simulating construction sites using the BIM model can help customers choose the right rental equipment. Building Information Modeling is an intelligent 3D model-based process that gives architecture and construction professionals the insight and tools they need to plan, design, construct and manage building and infrastructure projects more efficiently. BIM is transforming the traditionally siloed architecture, engineering and construction disciplines, allowing better collaboration and enhanced communication from the earliest stages of a project through completion. Integrating equipment access into BIM modelling at this early stage can offer significant benefits to all concerned.

Project planning benefits

BIM has fundamentally changed the way construction projects are approached. Historically, the building design process was very linear with little control over how information was being passed back and forth between the client, design engineers, architects and contractors.Information was generally provided in the form of a two-dimensional print describing a highly complex, three-dimensional job site. This print was often misinterpreted during the planning stage and design changes frequently got lost, resulting in costly rework and time inefficiencies during construction.

BIM models of all types are now available to help better align project stakeholders in the early stages of a project and to provide a single go-to source of information. These BIM models allow companies to more effectively visualize, plan, then simulate a construction project with three-dimensional detail. These simulations can then be reviewed by all those who will help execute the actual construction before the job begins, allowing for identification of potential challenges and healthy input around how to best optimize the process once onsite. This more robust upfront planning minimizes potential challenges while onsite to keep projects on time and reduce or eliminate unexpected costs.

Streamlined equipment planning

Architectural design and engineering are at the core of every new construction project. Once that work is complete, the bid process can begin. For bids to be accurate, logistics planning in terms of materials and equipment must be considered.

To facilitate better equipment planning on large construction projects, many equipment manufacturers now offer select BIM models, with some, like JLG, offering BIM models for the full equipment line. JLG hosts and maintains its BIM model library on JLG.com, which allows for live updates to machine specs as changes are made. So users will always know they have the most up-to-date information. Additionally, the models are hosted on bimobject.com, targeting a broader group of users leveraging this technology.

Contractors bidding on work can download these data-rich BIM equipment models and place them in simulated job site environments to ensure they choose the right machine(s) for the work and the space in which they will be used. They can even “load” them onto trucks and virtually deliver the units to the job site to determine the most efficient path to where the unit will be used.

Pre-planning during the bid process using BIM equipment models helps users more accurately plan for the equipment they need. For rental companies, a major advantage of BIM is they can get involved in the project in the early design and planning stages, increasing customer confidence in machine availability and building early relationships with the general contractor and sub-contractors. This provides peace of mind for the contractor through having a complete view of what is needed and when. Early engagement enables machines to be at the ready, with delivery planned to yield the greatest utilization.

The BIM model was used to select the JLG 1255 telehandler as the ideal equipment for the construction and installation process of the 14-foot-tall spherical sculpture erected on the Mississippi riverfront.

Case study: Building success with BIM

To honour its 100-year anniversary in 2018, the Rotary Club of Baton Rouge, La., donated a 14-foot-tall spherical sculpture to be installed on the Mississippi riverfront. The Rotary Club tapped the JLG BIM library from the initial planning stages of the project, choosing the JLG 1255 telehandler model. By using the 3D BIM model of the 1255, they were able to determine it could be used from the start of construction through final installation of the sculpture.

Since the structure was being built and installed on the Mississippi riverfront, it presented its fair share of challenges – not the least of which was extremely limited space requirements on the levee. “One wrong little step and you would’ve been hearing about this on the news,” said Mark Kenney, rigging engineer on the project.

By using a BIM model, Kenney and his team were able to identify the JLG 1255 telehandler as the right unit with a high degree of confidence. The 3D BIM model’s precise specifications allowed them to visualize its exact placement on the levee and share that information with the Rotary Club and the sculpture’s artist for planning purposes.

“Using BIM allowed us to visualize its placement, which was much easier than looking at a specifications sheet,” Kenney said. “Since it was a 3D model, we were able to show the customer how we planned to complete the job. It worked out really well.”

Using the JLG 1255 telehandler, the crew unloaded each of the sculpture’s three primary pieces with the carriage and forks. However, the outer shell of the sculpture was too large to ship as one piece. Split down the middle in two halves, the outer piece needed to be connected, then installed, while being held aloft so as not to scar the reflective, stainless-steel surface. Fortunately, thanks to effective planning with the BIM model and prior communication with JLG, the team knew they had exactly the right equipment to get the job done.

“The telehandler lifting hook attachment turned out to be the best accessory to use due to space restrictions and flexibility,” said David Bondurant, manager of the rigging department on the project. In coordination with a 165-ton-capacity crane, the JLG 1255 telehandler’s lifting hook attachment helped manipulate each piece into position.

The success of this project was largely attributed to the use of BIM. By placing BIM models into the actual plans, the contractor was able to confidently specify the equipment and accessory selection that would get the job done on time and within budget.

BIM for the long haul

Architects and engineers develop amazing designs that continue to modernize building and infrastructure projects around the world every day. BIM facilitates planning not only for the construction phase, but for the post-construction maintenance phase. By using equipment models early in the design phase we have seen some architects include access and areas for machine storage to keep building maintenance costs down by eliminating the need to prepare the site when machines are used. For one project, concrete loads were increased in select areas of the facility to allow the use of JLG 1850 Ultra Boom lifts for long-term maintenance.

BIM is enabling much deeper planning and understanding of projects. It has so many uses already, with more being uncovered almost daily. JLG is proud to be a leader in this space. The company sees offering BIM models to its customers as a valuable tool that will drive greater efficiencies throughout the construction process. JLG offers three levels of BIM models today, from free to a subscription-based service to companies who desire a branded library of BIM models to its customer base.

JLG continues to grow its connected solutions offering. Its line of access equipment gets the company onto many jobs. However, understanding the need for advanced equipment solutions through digital tools like BIM helps the company provide added value to its customers.

Print this page

Leave a Reply