Concrete showcase Great new products to help your customers finish concrete.

By Canadian Rental Staff

Products Allen brokk dragon epiroc mecalac Milwaukee minnich pusher toroYour customers will appreciate these advanced solutions for preparing and finishing concrete surfaces.

Cordless electric breaker

milwaukeetool.ca

Part of the new Milwaukee MX Fuel equipment system, the MX Fuel breaker is the industry’s first cordless breaker. Pulverizing up to two tons of concrete on a single charge, users experience the run-time required to break a 40-foot long trench, 12 inches wide and six inches deep. The MX Fuel breaker is lighter, weighing just 63.9 pounds. With easy manoeuverability and portability, this breaker transports quickly and safely to and from the jobsite. With an ergonomically enhanced grip and a 70 per cent lower vibration rate than corded breakers, the MX Fuel hits 30 per cent harder with 50 foot-pounds of impact energy, making it a safer option for prolonged use. Tripping hazards on the worksite have been eliminated with no compressor hose or extension cord to contend with and without ever tripping electrical breakers. The MX Fuel’s RedLithium CP203 battery pack charges in 45 minutes with the XC406 batteries charging in 90 minutes.

Part of the new Milwaukee MX Fuel equipment system, the MX Fuel breaker is the industry’s first cordless breaker. Pulverizing up to two tons of concrete on a single charge, users experience the run-time required to break a 40-foot long trench, 12 inches wide and six inches deep. The MX Fuel breaker is lighter, weighing just 63.9 pounds. With easy manoeuverability and portability, this breaker transports quickly and safely to and from the jobsite. With an ergonomically enhanced grip and a 70 per cent lower vibration rate than corded breakers, the MX Fuel hits 30 per cent harder with 50 foot-pounds of impact energy, making it a safer option for prolonged use. Tripping hazards on the worksite have been eliminated with no compressor hose or extension cord to contend with and without ever tripping electrical breakers. The MX Fuel’s RedLithium CP203 battery pack charges in 45 minutes with the XC406 batteries charging in 90 minutes.

For demanding rental applications

minnich-mfg.com

Minnich Manufacturing has introduced a new 50-cubic centimeter, gas-powered, backpack concrete vibrator to the rental market. Driven by a powerful Honda 50 cc motor with an ergonomically designed, fully adjustable harness, the lightweight 20.5-pound back pack concrete vibrator offers operators outstanding mobility, reliable performance, superior comfort and reduced fatigue during concrete consolidation. The 50 cc unit joins the 35 cc model in the Minnich back pack vibrator lineup. The Honda GX50 general-purpose engine expands the Minnich mini-four-stroke vibrator lineup with a model that offers high output and light weight for excellent performance and fuel efficiency in more demanding commercial and rental applications. Featuring a compact and lightweight design, the GX50 is the first Honda four-stroke model in the two-horsepower class that is 360-degrees inclinable during operation and storage. Minnich’s 50 cc backpack concrete vibrator is equipped with many new features, including a removable throttle assembly which enables operators to relocate the throttle for easy and comfortable operation. All core/casings and vibrator heads are interchangeable between all Minnich gas-powered and electric flex-shaft units with a true universal quick disconnect system, giving contractors equipment flexibility. Additional benefits include easy starting, low noise, simple maintenance, superb acceleration, and low fuel and oil consumption.

Minnich Manufacturing has introduced a new 50-cubic centimeter, gas-powered, backpack concrete vibrator to the rental market. Driven by a powerful Honda 50 cc motor with an ergonomically designed, fully adjustable harness, the lightweight 20.5-pound back pack concrete vibrator offers operators outstanding mobility, reliable performance, superior comfort and reduced fatigue during concrete consolidation. The 50 cc unit joins the 35 cc model in the Minnich back pack vibrator lineup. The Honda GX50 general-purpose engine expands the Minnich mini-four-stroke vibrator lineup with a model that offers high output and light weight for excellent performance and fuel efficiency in more demanding commercial and rental applications. Featuring a compact and lightweight design, the GX50 is the first Honda four-stroke model in the two-horsepower class that is 360-degrees inclinable during operation and storage. Minnich’s 50 cc backpack concrete vibrator is equipped with many new features, including a removable throttle assembly which enables operators to relocate the throttle for easy and comfortable operation. All core/casings and vibrator heads are interchangeable between all Minnich gas-powered and electric flex-shaft units with a true universal quick disconnect system, giving contractors equipment flexibility. Additional benefits include easy starting, low noise, simple maintenance, superb acceleration, and low fuel and oil consumption.

Morale-booster

dragonscreed.com

Dragon Screed’s design allows customers to screed subgrade for a uniform thickness of concrete and screed concrete from the comfort of the machine. It is quickly customizable to meet the needs of almost any project. Born out of 40 years of experience pouring concrete, the Dragon design screeds base materials and concrete faster and with less labour than other methods. Dragon Screed can be used in the offset position to screed on either side of the machine and operated in forward or reverse and also in front of the machine. It is quickly and easily adjustable to pour from four to 32 feet wide and accomplish radius pours up to 70 feet in diameter. Dragon Screed drags, floats and vibrates the concrete with every pass. Dragon Screed uses a hydraulic pivot that allows users to pour on a pitch if the machine is on an uneven surface. It features wide floats that drag smoothly behind the screed bar, each with a vibator attached. The vibration system is a multi-speed, remote-controlled system that lets the spotter quickly adjust the intensity of the vibration needed. From large parking lots to residential driveways to municipal roadways, Dragon Screed drastically reduces labour. When the machine does the dragging customers see a 50 per cent reduction in labour, not just in the number of workers required but also in physical effort. Users simply get the grade material or concrete reasonably close to grade and Dragon Screed does the rest. With vibration floats integrated into the screeding process, concrete finishers will be well-rested and able to dedicate their full attention and energy to those all-important finishing touches. Contractors experience a morale boost that leads to better employee retention, eliminating those troubles finding help on pour days.

Dragon Screed’s design allows customers to screed subgrade for a uniform thickness of concrete and screed concrete from the comfort of the machine. It is quickly customizable to meet the needs of almost any project. Born out of 40 years of experience pouring concrete, the Dragon design screeds base materials and concrete faster and with less labour than other methods. Dragon Screed can be used in the offset position to screed on either side of the machine and operated in forward or reverse and also in front of the machine. It is quickly and easily adjustable to pour from four to 32 feet wide and accomplish radius pours up to 70 feet in diameter. Dragon Screed drags, floats and vibrates the concrete with every pass. Dragon Screed uses a hydraulic pivot that allows users to pour on a pitch if the machine is on an uneven surface. It features wide floats that drag smoothly behind the screed bar, each with a vibator attached. The vibration system is a multi-speed, remote-controlled system that lets the spotter quickly adjust the intensity of the vibration needed. From large parking lots to residential driveways to municipal roadways, Dragon Screed drastically reduces labour. When the machine does the dragging customers see a 50 per cent reduction in labour, not just in the number of workers required but also in physical effort. Users simply get the grade material or concrete reasonably close to grade and Dragon Screed does the rest. With vibration floats integrated into the screeding process, concrete finishers will be well-rested and able to dedicate their full attention and energy to those all-important finishing touches. Contractors experience a morale boost that leads to better employee retention, eliminating those troubles finding help on pour days.

Quick-change tubs

electricdumper.com

The E-750 electric wheelbarrow is a partner for concrete, demolition and hauling needs. Power Pusher’s E-750 electric wheelbarrow with slurry tub and concrete funnel cap attachments meets the unique application needs of the concrete industry. The poly slurry tub with its powder-coated steel rim holds a true 1/4 yard of liquid concrete or up to 12 cubic feet of dry material, minimizing material loss during transport. The concrete funnel cap fits on the slurry tub and funnels the slurry into narrow spaces like post holes and other tight areas. It is durable and easy to clean. Customers can quickly change from the slurry tub to a galvanized steel tub that works well for demolition and hauling. Both the slurry tub and the galvanized steel tub have a weight capacity of 1,000 pounds, improving safety and efficiency by eliminating the ergonomic challenges and delays associated with manual wheelbarrows. The E-750 can move at speeds reaching four miles per hour. Created to minimize stress and strain, the E-750 provides push-button powered dumping capability. Its silent motor with zero emissions is suitable for indoor or outdoor use, and it fits through standard doors. Multiple standard and custom quick-change attachments are available.

The E-750 electric wheelbarrow is a partner for concrete, demolition and hauling needs. Power Pusher’s E-750 electric wheelbarrow with slurry tub and concrete funnel cap attachments meets the unique application needs of the concrete industry. The poly slurry tub with its powder-coated steel rim holds a true 1/4 yard of liquid concrete or up to 12 cubic feet of dry material, minimizing material loss during transport. The concrete funnel cap fits on the slurry tub and funnels the slurry into narrow spaces like post holes and other tight areas. It is durable and easy to clean. Customers can quickly change from the slurry tub to a galvanized steel tub that works well for demolition and hauling. Both the slurry tub and the galvanized steel tub have a weight capacity of 1,000 pounds, improving safety and efficiency by eliminating the ergonomic challenges and delays associated with manual wheelbarrows. The E-750 can move at speeds reaching four miles per hour. Created to minimize stress and strain, the E-750 provides push-button powered dumping capability. Its silent motor with zero emissions is suitable for indoor or outdoor use, and it fits through standard doors. Multiple standard and custom quick-change attachments are available.

Polish right to wall

alleneng.com

Allen has introduced its new RP235 and RP245 polishing riders. The RP235 and RP245 were designed with the high-volume concrete polisher in mind. These riding trowels come as designed to achieve high rotor speeds to achieve high torque while polishing. They also come equipped with special dolly jacks that ensure transportation indoors can be done with ease, as well as allowing for quick change of the polishing pads. These designs are built on Allen’s popular edging riding trowel frame to allow contractors to get extremely close to the wall while polishing.

Allen has introduced its new RP235 and RP245 polishing riders. The RP235 and RP245 were designed with the high-volume concrete polisher in mind. These riding trowels come as designed to achieve high rotor speeds to achieve high torque while polishing. They also come equipped with special dolly jacks that ensure transportation indoors can be done with ease, as well as allowing for quick change of the polishing pads. These designs are built on Allen’s popular edging riding trowel frame to allow contractors to get extremely close to the wall while polishing.

Seven times faster

brokk.com

Brokk offers the BCP planer attachment for controlled material removal on walls, floors and ceilings for cleaning, renovation and restoration applications. The three models in the BCP series are specially designed to work with Brokk remote-control demolition machines and offer up to seven times the speed of handheld options while providing greater precision and safety for grinding, brushing or removing concrete, glue, carpet, tile and other materials. Hood and vacuum connections are also available, enabling operation in contaminated environments such as asbestos and nuclear applications. The high-efficiency BCP planer offers contractors a new option for quickly and precisely removing deteriorated or contaminated concrete, adhesives or other materials in a number of applications including industrial cleaning, abatement, bridge repair and many more. With a maximum cutting depth of 1/4 inch per pass (1/2 inch combined) and automatic leveling in all directions, the BCP Planer provides high-quality, even removal across a wide area, unlike handheld options which often provide uneven results. For hazardous material removal, this creates significant savings by removing only the contaminated material and reducing waste handling costs. The BCP planer offers 360-degree rotation, which allows contractors to work at any angle, including overhead, for maximum efficiency. A selection of cutting drums for different operations further increases versatility. And with drum replacement taking less than five minutes, contractors can quickly switch from removing concrete to removing plaster, glue and asbestos.

Brokk offers the BCP planer attachment for controlled material removal on walls, floors and ceilings for cleaning, renovation and restoration applications. The three models in the BCP series are specially designed to work with Brokk remote-control demolition machines and offer up to seven times the speed of handheld options while providing greater precision and safety for grinding, brushing or removing concrete, glue, carpet, tile and other materials. Hood and vacuum connections are also available, enabling operation in contaminated environments such as asbestos and nuclear applications. The high-efficiency BCP planer offers contractors a new option for quickly and precisely removing deteriorated or contaminated concrete, adhesives or other materials in a number of applications including industrial cleaning, abatement, bridge repair and many more. With a maximum cutting depth of 1/4 inch per pass (1/2 inch combined) and automatic leveling in all directions, the BCP Planer provides high-quality, even removal across a wide area, unlike handheld options which often provide uneven results. For hazardous material removal, this creates significant savings by removing only the contaminated material and reducing waste handling costs. The BCP planer offers 360-degree rotation, which allows contractors to work at any angle, including overhead, for maximum efficiency. A selection of cutting drums for different operations further increases versatility. And with drum replacement taking less than five minutes, contractors can quickly switch from removing concrete to removing plaster, glue and asbestos.

Uniform curbs

curbroller.com

Curb Roller Manufacturing has introduced the Curb Roller CM4000: a single-operator machine for shaping concrete for curb and gutter work. The CM4000 reduces the labour of shaping curb and gutter pours, allowing crews to complete work up to twice as fast as manual methods or face forming. The Curb Roller CM4000 is most commonly used for curb and gutter projects ranging from 50 to 5,000 linear feet and can be used on jobs of all types and sizes, including patch and repair jobs. The system has also been widely accepted as an efficient method to tackle small v-gutter and flume projects. Customers can choose from more than 25 pre-designed drum profiles or fit the unit with a custom drum made to their project’s specifications. The CM4000 gives large and small contractors the ability to do a broader scope of work without having to invest in large, expensive equipment. Because the drums can be easily switched out, contractors can offer multiple curb styles after investing in the base machine. The single-operator machine takes most of the back-breaking work out of curb and gutter work, all while producing a consistent, high-quality finished product. The equipment is intuitive to use, making it accessible for workers who might not have as much experience. The CM4000 has a patented guide ring that runs on the inside of forms, ensuring a uniform curb every time.

Curb Roller Manufacturing has introduced the Curb Roller CM4000: a single-operator machine for shaping concrete for curb and gutter work. The CM4000 reduces the labour of shaping curb and gutter pours, allowing crews to complete work up to twice as fast as manual methods or face forming. The Curb Roller CM4000 is most commonly used for curb and gutter projects ranging from 50 to 5,000 linear feet and can be used on jobs of all types and sizes, including patch and repair jobs. The system has also been widely accepted as an efficient method to tackle small v-gutter and flume projects. Customers can choose from more than 25 pre-designed drum profiles or fit the unit with a custom drum made to their project’s specifications. The CM4000 gives large and small contractors the ability to do a broader scope of work without having to invest in large, expensive equipment. Because the drums can be easily switched out, contractors can offer multiple curb styles after investing in the base machine. The single-operator machine takes most of the back-breaking work out of curb and gutter work, all while producing a consistent, high-quality finished product. The equipment is intuitive to use, making it accessible for workers who might not have as much experience. The CM4000 has a patented guide ring that runs on the inside of forms, ensuring a uniform curb every time.

Self-acting movement

epiroc.com

Epiroc has added two new models for heavier carriers to its popular CB Concrete Buster range. The CB 5500 and CB 7500 are designed for carriers in the 50- to 85-ton weight class. Due to their comparatively light weights, CB Concrete Busters are effective choices for use with high-reach or long-front carriers. They are ideal for applications with highly abrasive material and low visibility of the product in operation. They are also suitable where noise is an issue and they can be used in residential areas where hydraulic breakers are not permitted. As construction and demolition contractors worldwide have discovered, CB Concrete Busters with their wide jaw openings and high cracking forces, are ideal for demolishing thick foundation walls and they make light work of cracking girders and heavy concrete at extreme heights. CB Concrete Busters are equipped with two powerful hydraulic cylinders which deliver virtually continuous closing force for maximum productivity. The hydraulic cylinders are fully protected by piston rod guards. An integrated speed valve gives faster working cycles. Offering impressive cracking forces of up to 190 tons depending on the model, CB Concrete Busters are equipped with two independently moving jaws that eliminate displacement force, thus lowering stress levels. Cutting blades are both replaceable and reversible. A productive feature on all CB Concrete Busters is 360-degree endless hydraulic rotation, which allows precise handling and optimal positioning. If the cutter grips the material at an oblique angle a built-in pressure relief valve allows a “self-acting movement” that brings the cutter jaw into the ideal position. This valve effectively protects both the carrier and the cutter from potentially damaging reaction forces.

Epiroc has added two new models for heavier carriers to its popular CB Concrete Buster range. The CB 5500 and CB 7500 are designed for carriers in the 50- to 85-ton weight class. Due to their comparatively light weights, CB Concrete Busters are effective choices for use with high-reach or long-front carriers. They are ideal for applications with highly abrasive material and low visibility of the product in operation. They are also suitable where noise is an issue and they can be used in residential areas where hydraulic breakers are not permitted. As construction and demolition contractors worldwide have discovered, CB Concrete Busters with their wide jaw openings and high cracking forces, are ideal for demolishing thick foundation walls and they make light work of cracking girders and heavy concrete at extreme heights. CB Concrete Busters are equipped with two powerful hydraulic cylinders which deliver virtually continuous closing force for maximum productivity. The hydraulic cylinders are fully protected by piston rod guards. An integrated speed valve gives faster working cycles. Offering impressive cracking forces of up to 190 tons depending on the model, CB Concrete Busters are equipped with two independently moving jaws that eliminate displacement force, thus lowering stress levels. Cutting blades are both replaceable and reversible. A productive feature on all CB Concrete Busters is 360-degree endless hydraulic rotation, which allows precise handling and optimal positioning. If the cutter grips the material at an oblique angle a built-in pressure relief valve allows a “self-acting movement” that brings the cutter jaw into the ideal position. This valve effectively protects both the carrier and the cutter from potentially damaging reaction forces.

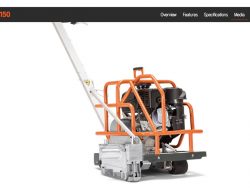

Early cutting

husqvarna.com

The new Husqvarna Soff-Cut 150 E is an electric version of the gas-powered Husqvarna Soff-Cut 150, which has become popular among contractors due to its reliable performance, low weight, swift handling and excellent results. The new electric version delivers additional benefits such as easier transportation, less noise, low maintenance and no exhaust fumes, which allows for indoor sawing. Due to its smooth electric motor, which vibrates less than a gas engine, the new machine produces cleaner and more even contracting joints. Just like the bigger Soff-Cut machines, the 150 E model is equipped with Husqvarna’s patented antiravel skid plate and Soff-Cut XL diamond blades. The blade block enclosure minimizes noise and is equipped with a vacuum port for easy dust control. Husqvarna Soff-Cut is a unique patented system for ultra-early entry concrete sawing. This technology enables concrete to be cut within the first one or two hours after finishing and before final set. Husqvarna Soff-Cut provides the best solution for minimizing the risk of random cracking, and simplifies the working process compared to conventional sawing.

The new Husqvarna Soff-Cut 150 E is an electric version of the gas-powered Husqvarna Soff-Cut 150, which has become popular among contractors due to its reliable performance, low weight, swift handling and excellent results. The new electric version delivers additional benefits such as easier transportation, less noise, low maintenance and no exhaust fumes, which allows for indoor sawing. Due to its smooth electric motor, which vibrates less than a gas engine, the new machine produces cleaner and more even contracting joints. Just like the bigger Soff-Cut machines, the 150 E model is equipped with Husqvarna’s patented antiravel skid plate and Soff-Cut XL diamond blades. The blade block enclosure minimizes noise and is equipped with a vacuum port for easy dust control. Husqvarna Soff-Cut is a unique patented system for ultra-early entry concrete sawing. This technology enables concrete to be cut within the first one or two hours after finishing and before final set. Husqvarna Soff-Cut provides the best solution for minimizing the risk of random cracking, and simplifies the working process compared to conventional sawing.

Telematics package

mecalac.com

Mecalac has introduced the TA3SH Power Swivel site dumper for increased versatility and safety on jobsites. The site dumper is part of the TA3 range, which is designed for the small to medium jobsite, and is particularly useful in crowded or confined areas. Like all Power Swivel site dumpers from Mecalac, the TA3SH is designed to deliver superior versatility and performance, especially on confined jobsites such as housing developments or landscaping projects. The TA3SH is 13 feet long and six feet, one inch wide. The Power Swivel technology features forward and swivel tipping mechanisms, allowing the load to rotate 90 degrees on either side before being tipped. This reduces the need to move equipment, enhancing productivity. The Mecalac range of Power Swivel site dumpers features payload options from one to 10 tons. The TA3SH’s payload capacity is 6,613 pounds, making it ideal for industries such as concrete, landscaping and urban construction. All Power Swivel site dumpers feature a heavy-duty locking device. This keeps the skip facing forward while on the move and is just one of many features that ensures Mecalac Power Swivel models provide the highest level of safety.

Mecalac has introduced the TA3SH Power Swivel site dumper for increased versatility and safety on jobsites. The site dumper is part of the TA3 range, which is designed for the small to medium jobsite, and is particularly useful in crowded or confined areas. Like all Power Swivel site dumpers from Mecalac, the TA3SH is designed to deliver superior versatility and performance, especially on confined jobsites such as housing developments or landscaping projects. The TA3SH is 13 feet long and six feet, one inch wide. The Power Swivel technology features forward and swivel tipping mechanisms, allowing the load to rotate 90 degrees on either side before being tipped. This reduces the need to move equipment, enhancing productivity. The Mecalac range of Power Swivel site dumpers features payload options from one to 10 tons. The TA3SH’s payload capacity is 6,613 pounds, making it ideal for industries such as concrete, landscaping and urban construction. All Power Swivel site dumpers feature a heavy-duty locking device. This keeps the skip facing forward while on the move and is just one of many features that ensures Mecalac Power Swivel models provide the highest level of safety.

Available technologies include start/stop control, capture and hazard detection. Start/stop control improves on-site safety, minimizes fuel consumption and increases service intervals by automatically starting and stopping the engine in predetermined conditions. Capture is Mecalac’s innovative telematics solution, allowing rental centers and site managers to monitor unit location, distance traveled and hours completed each day. Hazard detection uses a microwave radar to provide flawless obstacle detection, further increasing safety on jobsites.

Perfect blade angles

toro.com

Toro power trowels feature contoured adjustable handles and a rotating stabilizing ring for precise handling that will deliver a smooth concrete finish. There are four models to choose from and each comes equipped with a Honda engine. The Toro Dyna-Clutch safety feature is incorporated into each unit and will stop the blade without shutting down the engine. The PT-36PP and PT-46PP feature Toro’s patented Pro-Pitch blade adjustment system that provides smooth, quick pitch changes to ensure blades are at the optimal angle for a perfect finish.

Toro power trowels feature contoured adjustable handles and a rotating stabilizing ring for precise handling that will deliver a smooth concrete finish. There are four models to choose from and each comes equipped with a Honda engine. The Toro Dyna-Clutch safety feature is incorporated into each unit and will stop the blade without shutting down the engine. The PT-36PP and PT-46PP feature Toro’s patented Pro-Pitch blade adjustment system that provides smooth, quick pitch changes to ensure blades are at the optimal angle for a perfect finish.

Plate steel construction

concretekangaroo.com

The Concrete Kangaroo helps contractors maximize profits by placing large or small amounts of concrete safely and effectively the first time. It frees up manpower by securely attaching to skid steers or other equipment, reducing concrete and labour costs. The Concrete Kangaroo is made to be extremely resilient and strong. The sidewalls and door are made from 3/16-inch plate steel. It has a capacity of 3/4 cubic yard and weighs 500 pounds. To make cleaning easy, the entire dispenser is primed and painted in gloss black. To make any concreting job easy, the Concrete Kangaroo comes with a variety of extra features. The step-and-grab handle and hydraulic door opener make it exceptionally easy to move and operate. It’s designed to fit all skid steers with universal quick-attach systems and fits into the back of most pickup trucks.

The Concrete Kangaroo helps contractors maximize profits by placing large or small amounts of concrete safely and effectively the first time. It frees up manpower by securely attaching to skid steers or other equipment, reducing concrete and labour costs. The Concrete Kangaroo is made to be extremely resilient and strong. The sidewalls and door are made from 3/16-inch plate steel. It has a capacity of 3/4 cubic yard and weighs 500 pounds. To make cleaning easy, the entire dispenser is primed and painted in gloss black. To make any concreting job easy, the Concrete Kangaroo comes with a variety of extra features. The step-and-grab handle and hydraulic door opener make it exceptionally easy to move and operate. It’s designed to fit all skid steers with universal quick-attach systems and fits into the back of most pickup trucks.

Great power-to-weight ratio

ligchine.com

Ligchine has introduced the SpiderScreed Series – a compact, lightweight and manoeuverable drive-in system designed for upper deck concrete and slab-on-grade screeding applications. The drive-in SpiderScreed machine was designed to be lightweight and powerful, featuring a 100-per cent TIG-welded tubular aluminum cage design that keeps overall weight down to approximately 1,280 pounds. Its patent-pending three-wheel Versa-Drive system delievers independent zero-turn drive, up to 90-degree horizontal drive and lateral drive. It offers superior power-to-weight ratio (55 pounds per horsepower), allowing lower slumps and cooler running at all times. It also incorporates Ligchine’s patented machine-leveling system to ensure flatter floors and greater compaction than simple screed head-only leveling systems.

Ligchine has introduced the SpiderScreed Series – a compact, lightweight and manoeuverable drive-in system designed for upper deck concrete and slab-on-grade screeding applications. The drive-in SpiderScreed machine was designed to be lightweight and powerful, featuring a 100-per cent TIG-welded tubular aluminum cage design that keeps overall weight down to approximately 1,280 pounds. Its patent-pending three-wheel Versa-Drive system delievers independent zero-turn drive, up to 90-degree horizontal drive and lateral drive. It offers superior power-to-weight ratio (55 pounds per horsepower), allowing lower slumps and cooler running at all times. It also incorporates Ligchine’s patented machine-leveling system to ensure flatter floors and greater compaction than simple screed head-only leveling systems.

Print this page

Leave a Reply